Pyrolysis Systems

The IQ Pyrolysis process is a safe and controlled oxygen free process to produce a high quality renewable natural gas (RNG) from waste feedstocks. These gases can then be used for energy production, through onsite gas fuelled CHP power generator systems, other existing NG type infrastructure and facilities, such as NG delivery and distribution pipelines and existing NG power generation plants. The other option with dirty and mixed plastics is an advanced recycling pathway and condensing the gas down to an oil to be used for plastic production. These processes result in a cool, clean flue gas with negligible emissions and a very efficient extraction of useful resources from the waste. The IQ Pyrolyser also produces other safe and clean resources, such as biochar or a char/ash depending on the feedstock and clean water, which all have a use in agricultural or industrial purposes.

Key Facts

- Unique ultra low turbulence Counter-Flow bed design

- Process capacity ranging from 700 kg/hr up to 5000 kg/hr and higher

- All machinery is FAT tested before delivery

- Satellite Control (SCADA), monitoring, training

- Onboard generator to provide power and heat for the continuous pyrolysis process

- Onboard NOx removal/SNCR – 2 sec @980C Retention – Full Enviro Skid/Scrubber/Quench/PM Removal

- Capable of processing very high moisture content waste – up to 85% MC (with dryers)

- All controls and drivers included in onboard MCC

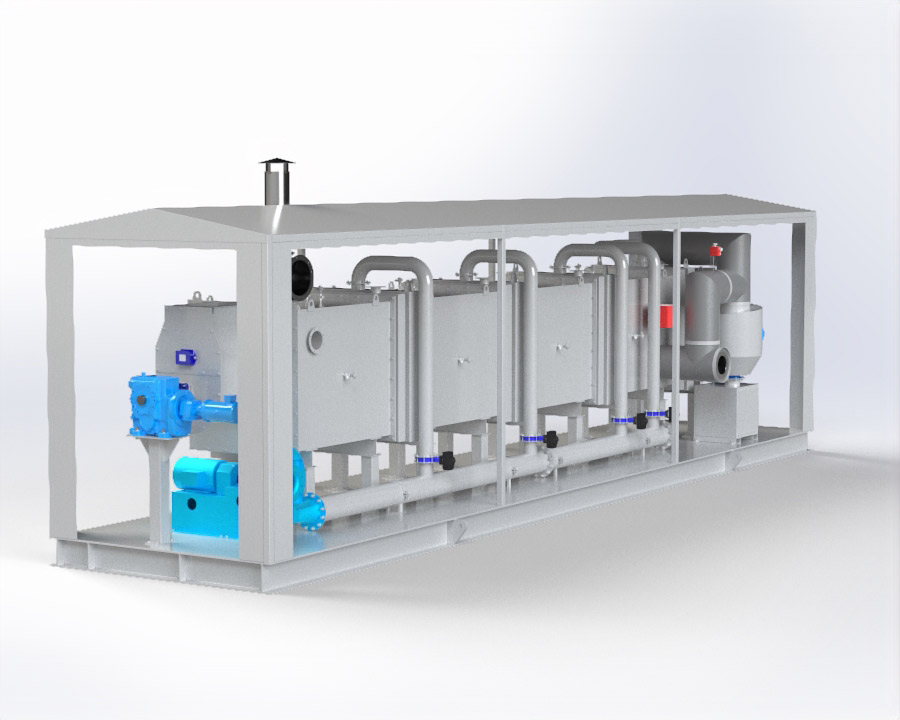

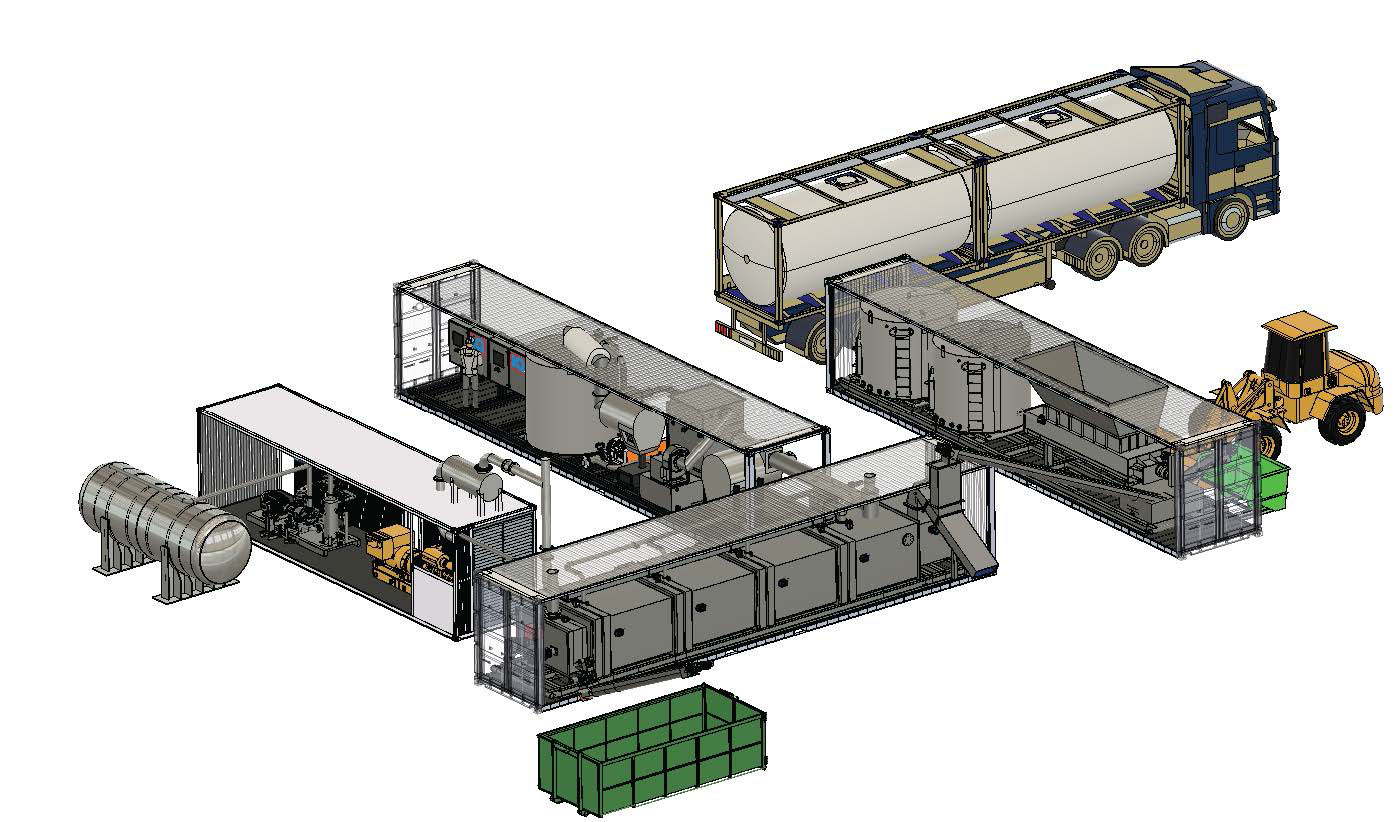

- Delivers in four skids and assembles and commissions in days

Pyrolysis- Inputs & Outputs

Waste Input

Mixed Wastes (MSW)

Tire Waste

Forestery Slash

Agriculture Wastes

Sewage Sludge

Medical Waste

Legacy Waste

Mixed Organics

Dried Waste (~15-20%MC)

Gasification Unit Output

Renewable Natural Gas (RNG), can be used for:

- Power Generation - Onsite or Offsite Use, e.g. natural gas replacement - Advanced Recycling -condensing it to an oil if the target is plastic

Biochar or Char/Ash

Hot Water/Steam

Unit Examples

Commercial Pyrolysis Unit (HTP1000) – Alberta

The first modular pyrolysis (HTP1000) unit is currently being manufactured in Canada. This unit can convert biomass or mixed waste into syngas or oil.

Sizing

Pyrolysis (HTP1000) Unit

Processes ~8,000 tonnes/annum (1 t/hour) of dried feedstock

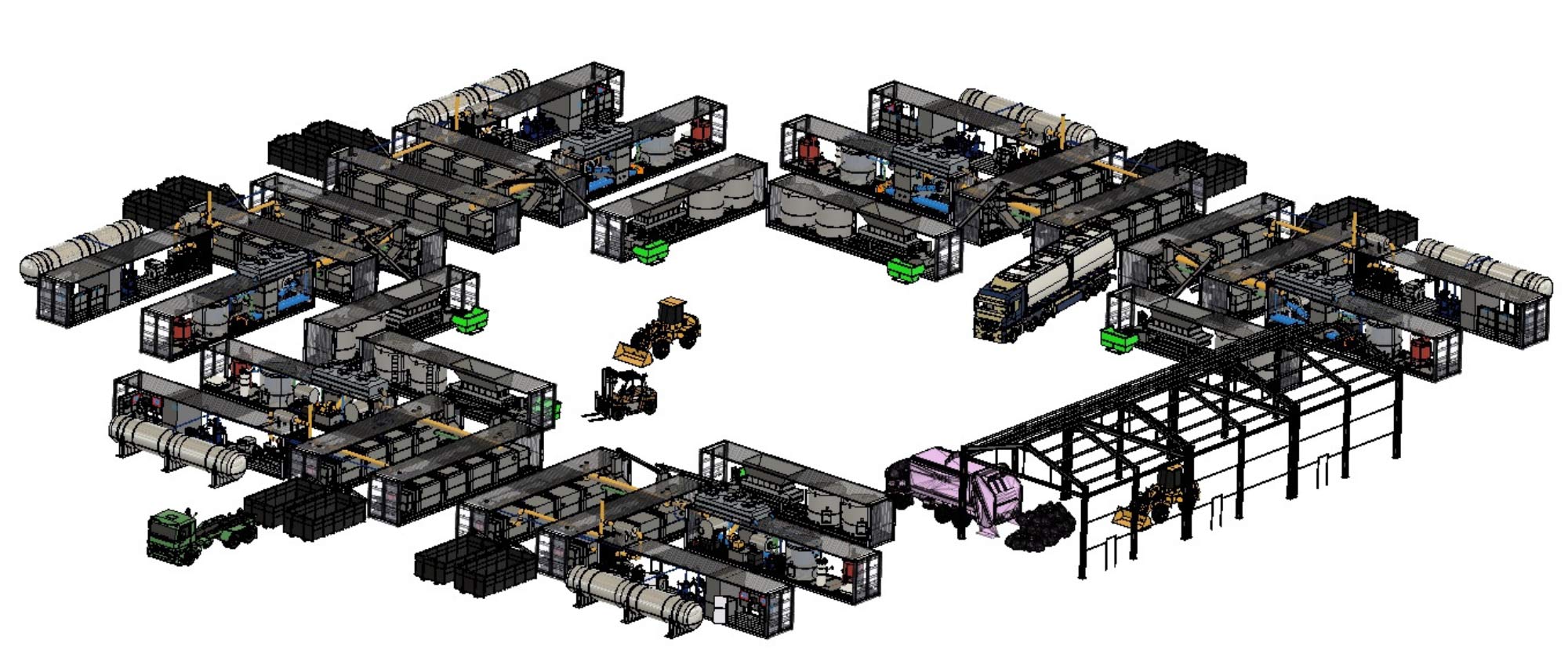

12 x Pyrolysis (HTP1000) Unit

Processes ~96,000 tonnes/annum (12t/hour) of dried feedstock