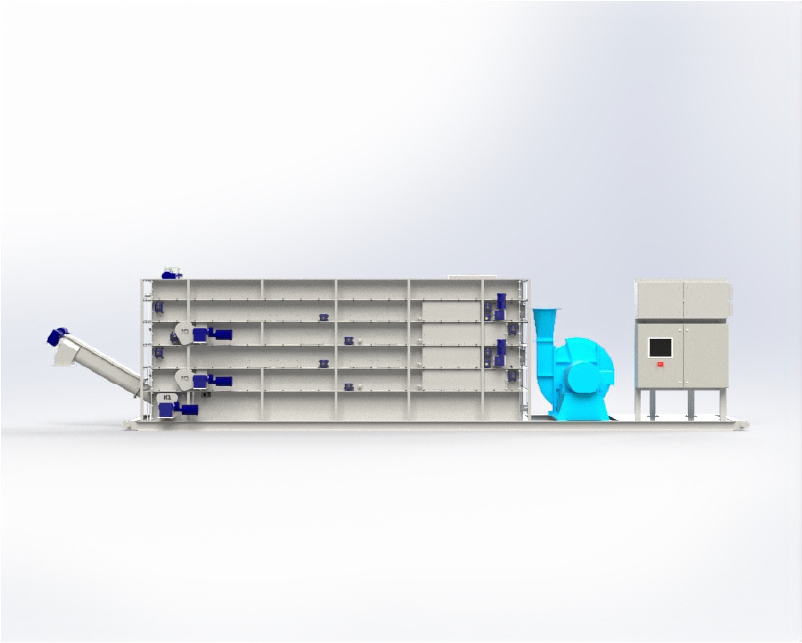

Indirect Dryer Systems

The indirect dryer unit has been designed with the decades of experience of handling biomass feedstocks from the previousthermal treatment projects that the IQ Energy team worked on. The indirect dryer unit slowly dries out the dewatered wasteinput continuously moving it across serpentine belts with heat applied indirectly (the heat not contacting the product). Thisprocess significantly reduces the weight and volume of the waste input and dries it to a valuable product for agriculture,industry or as an input to the thermal treatment process. The indirect dryer unit typically takes a dewatered waste input of~80-85% moisture content and dries this down to an easy to handle ~15-20%moisture content.

Key Facts

- Unique ultra low turbulence Counter-Flow bed design

- Built-in Extended Retention Chamber to target emerging contaminants, e.g. PFAS & microplastics.

- Process capacity ranging from 700 kg/hr up to 5000 kg/hr and higher

- Delivers in two to three skids and assembles and commissions in days

- Onboard NOx removal/SNCR – 2 sec @980C Retention – FullEnviro Skid/Scrubber/Quench/PM Removal

- Capable of processing very high moisture content waste – up to85% MC (with dryers)

- Satellite Control (SCADA), monitoring, training

- All controls and drivers included in onboard MCC

- All machinery is FAT tested before delivery

Gasification - Inputs & Outputs

Waste Input

Sewage Sludge

Agricultural Wastes

Digestates

Screenings & Legacy Wastes

Animal Wastes, e.g. Manures

Food Organics

Mixed Wastes (MSW)

Medical Waste

Dewatered Sludge (~80-85%MC)

Dried Product (~15-20%mc)

Indirect Dryer Output

Dried Product, used for:

- Agriculture - Industrial - Thermal Treatment Input

Residual Heat (80%)

Hot Water

Ability to Use A Wide Variety of Heat Sources

IQ Energy’s Indirect Dryer Unit can effectively use various heat sources for the drying process.This can include:

- Current onsite heat sources, like a cogeneration exhaust, flue gas or other onsite heat.

- Diesel or gas burners

- IQ Energy’s Carbonisation Units.

Unit Examples

Commercial G500 – Alberta

- Successfully operated on piggery manure.

- Moving to a commercial site in 2024 where it will process pulp sludge, biosolids & animal wastes, as well as other biomass and mixed feedstocks.

- Will supply dried feedstock (15-20% moisture content) to the IQ Energy carbonisation unit.