Applications

Advanced Recycling of Plastics

A Focus on Dirty & Mixed Plastics

The Problem

Despite the significant efforts and a many years of work, the vast majority of plastics still ends up in landfills or is disposed of via open burning or other environmentally damaging methods. It is estimated that as much as 85% of all waste plastic in Canada still ends up in landfills. This has a broad range of negative environmental impacts, as well as creating community frustration.

Currently there are many solutions being proposed for plastics, but the vast majority of these can only focus on certain types of plastics or require extensive pre-sorting and cleaning so that the plastic make them clean enough to be recycled. There are also other approaches which struggle to scale to the magnitude of waste that needs to be addressed and adapt to the logistical challenges of plastic waste. This creates challenges around addressing dirty and mixed plastic waste streams, competing for clean plastic waste streams and resources and costs to add additional equipment to achieve the minimum standards for certain technologies.

The IQ Energy Solution

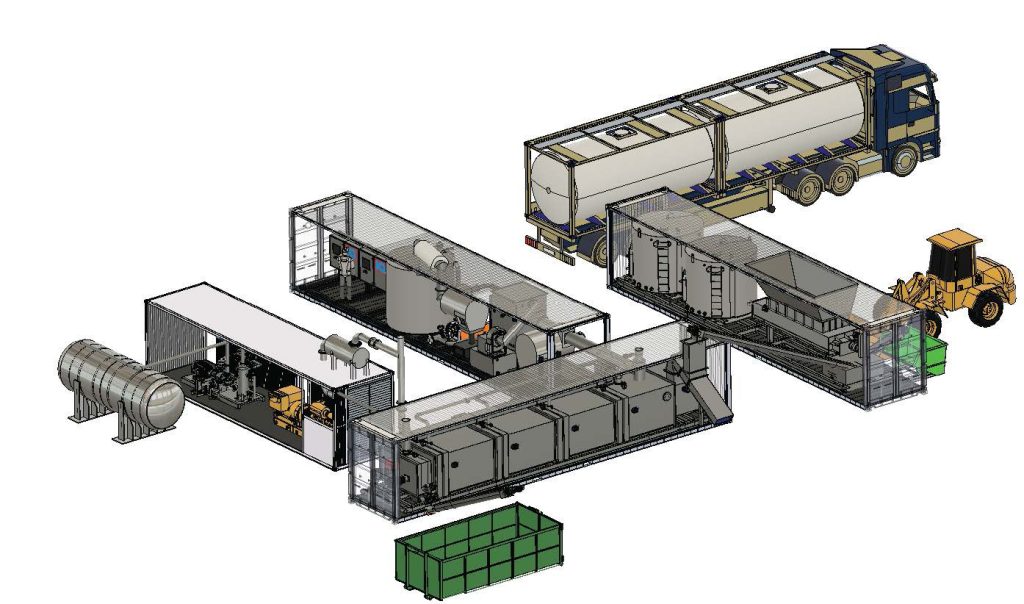

Modular, Containerised & Scalable Advanced Recycling (Pyrolysis) Units

- A manufactured pyrolysis unit that recycles dirty and mixed plastics back into a plastic-derived crude oil or gas that can be further refined into a variety of consumer or industrial products, including virgin plastics.

The novelty of the IQ Energy approach is the patented Thermal Molecular Sorting (TMS) process, accompanied by dry gas cleaning, this opens up the opportunity to address dirty and mixed plastics and recycle a higher volume of plastic molecules.

Repeatable and rapidly manufactured units allow affordable, scalable and replicable applications to suit a wide range of locations: urban, regional or remote.

The units are designed to be off-grid by generating their own power and heat and are financially viable even with minimal disposal fees.

A full commercial sized unit is currently being manufactured in Canada.

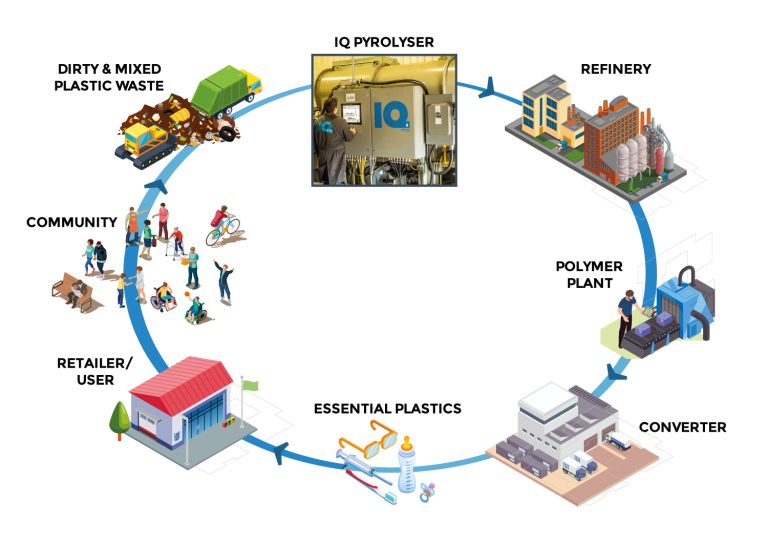

Thermal Molecular Sorting Process

Converting Dirty and Mixed plastics into Useful Resources for a Circular Economy.

- Dirty and Mixed Plastic Wastes

- Negligible Emissions

- Scales to the Waste Source

- Highly Automated with Remote Support

- Valuable Resources Produced

- Affordable and Beneficial Community Asset

- Legacy Waste Clean Ups

IQ Energy has developed a unique and patent pending ‘Thermal Molecular Sorting’ (TMS) pyrolysis process capable of sorting/separation of thermally produced pyrolysis gas species coming from the processing of a variety of waste feed stocks. The TMS process sorts the produced gasses from the solid inert materials present in the feedstock at the gaseous level effectively eliminating the need for commonly used and expensive MRF solids pre-sorting systems.

Using the IQ TMS process a broad range of mixed and dirty waste streams can be beneficially recycled as the waste materials are thermally converted from solid states into gaseous states by the IQ TMS process before being sorted and then reconstituted into valuable products, such as a plastic derived crude oil for plastic production. IQ’s ‘TMS’ pyrolysis systems also facilitate further upgrading of the various gas species produced by sorting them into narrower bands or groups, enhancing the value of the resulting liquid and gaseous products.

The TMS process also collects significant amounts of fixed carbon and carbon black for further beneficial uses. All recyclables, such as metal and glass are pre-separated at the start of the TMS process with residual metals, glass and minerals present in the bio-char coming out at the end of the process for recycling

Benefits of the IQ Energy Advanced Recycling Approach

Addressing Pressing Concerns

The need to address plastic waste in a way that scales: The thermal molecular sorting process provides a unique opportunity to address dirty and plastic wastes through cost-effective scalable units.

The need for more recycled content in packaging: Businesses are under pressure to have more recycled content within their packaging. Clean and sorted plastics can only provide so much recycled plastic recovery, our units open up new opportunities.

IQ Energy Units can have a significant positive impact on greenhouse gases by reducing the reliance on fossil fuels and sequestering carbon as a char.

Financial Benefits

Costs Savings: Self sustaining unit not needing added energy sources.

New Revenue Opportunities: Value to be placed on creating a plastic derived crude oil and a char/ash

Mitigating Risks

Modular units to help scale to the solution, as a centralised or decentralised plant.

Repeatable manufactured units with repeatable safe, trusted and clean outcomes helping to build trust by regulators and the community.

Manufactured and delivered onsite within 10-12 months to quickly address current challenges at a locked in price.

IQ Energy Pyrolysis Unit Sizes

In order to deal with the magnitude of the plastic waste problem solutions need to be able to scale effectively and affordably. IQ Energy’s Advanced Recycling approach allows this through cost savings through unit pairings and manufacturing repeatable units. Our approach provides the opportunity to approach the problem through single, hub and spoke or a centralised plant providing the flexibility for plant operators.

Featured in CSIRO Report: Advanced recycling technologies to address Australia's plastic waste

Report by the CSIRO: Australia’s National Science Agency.

Our profile can be found on page 25 of the report.